Cyclones vs Tanks: Details Competitors Leave Out

There’s a bold claim out there that cyclones can replace a classifying tank in every scenario. The trouble is, once the feed changes, cyclones start making inconsistent cuts.

PUBLISHED: NOVEMBER 2025

With deposits changing and sand specs getting stricter, Superior's technical sales manager for washing products breaks down what dealers really need to watch for when helping customers choose a wash system.

When you study history, how different is washing equipment today?

Bennington: You’ll sometimes hear “new technology” claims, but aside from computer controls, sand screws, cyclones, and classifying tanks have been around for about 140 years. They fundamentally work the same today as they did a century ago.

Even though the equipment hasn’t changed much, the material coming out of the ground has. Across North America, producers are dealing with tougher deposits that don’t yield as much good product, which means washing — and often classifying — is now the norm.

What are some good starting points dealers can consider when approaching end users about washing equipment?

Bennington: It sounds cliché, but you have to listen and take good notes. Most of the time, producers like to engage with someone about their challenges.

If they say, ‘I can’t make spec,’ and they’re running a screen and a screw – or even dry screening – that’s a clue they need more processing.

If they say ‘I have contamination,’ your next question should be: what kind? Now, we're getting down the path of getting information to provide a solution.

Are the days of one-size-fits-all washing solutions essentially gone?

Bennington: Correct — and that’s why the process can feel complicated. Every deposit behaves differently, so you can’t assume one setup will fit every site.

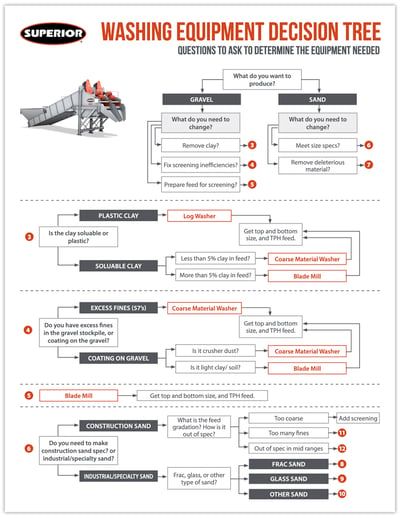

To help simplify things for dealers, we created a decision tree that flows through the right questions to ask your customers. It’s an easy way for anyone to narrow down what type of system the material might be pointing toward.

From there, the next step is usually a questionnaire. That’s where we gather the specific details engineering needs — tons per hour, feed gradation, moisture, spec requirements, and so on. Tools like these keep the early conversations focused and help us design solutions that actually solve the producer’s problem instead of guessing at it.

Are classifying tanks playing a bigger role in today’s plants?

Bennington: Yes. For example, when I started my career, most of the material extracted in the Upper Midwest was glacial till. If you ran that across a screen and washed the dirt off, you had C33 sand.

But that material is mostly gone. Now, producers are digging into older alluvial deposits with much more variability and clay content, which means more processing.

Just for fun, would you give the third dealer who calls you with the definition of “alluvial material” a $100 Cabela’s gift card?

Bennington: Absolutely! I'm standing by...

Let’s talk hydrocyclones and classifying tanks specifically. Where does each solution broadly apply?

Natural sand deposits usually follow a bell-curve gradation, from coarse +4 mesh down to fine -100 mesh and pan material. Your equipment choice comes down to where the excess material shows up in that curve.

- If there’s too much +4 or +8 mesh, you’re in screening territory.

- If there’s too much -100 mesh, you need screws or cyclones.

- If the excess sits in the 30s, 50s, or 100 mesh, that’s the classifying tank zone.

Some manufacturers claim a cyclone can replace a tank in every situation, but it can’t.

A cyclone makes a single cut, coarse one way and fines the other. If the feed varies, the products will vary right along with it, because you can’t tune a cyclone to tighten specs as the material changes. In consistent deposits, a cyclone-only setup can work. In variable natural sand, classifying tanks give you the control cyclones simply can’t.

How Does a Classifying Tank Work?

What should dealers know about cost and maintenance?

Classifying tanks are simple machines with little upkeep. The valves and elbows are made of urethane and can last up to 10 years. Electronics eventually need attention, but those can be swapped out in minutes.

Screws and cyclone-based plants carry a similar cost per ton, but the timing of those costs is different.

Screws have small, steady annual expenses like oil, wear shoes, and bearings.

Meanwhile, Spirit® Sand Plants with cyclones and dewatering screens have lighter routine wear. The cyclone apex is inexpensive and dewatering screens run for years. The pump is the major long-term cost, and it typically comes due every four to five years.

What about upfront cost? How is that steering end users these days?

Classifying tanks are expensive, but it's not a fair comparison to screws or cyclone plants. You either need a tank, or you don’t.

There is no substitute.

Other Content This Month

Built for Uptime: Inside PECO's New Flagship Facility

With centralized dispatch, larger service bays, and faster parts picking, Power Equipment is delivering faster, more efficient support across their territory.

9 Things We Already Know About CONEXPO-CON/AGG

Scheduled March 3–7, the show is already coming into focus. Here, we’ve gathered some early insights to give dealers a head start on what’s ahead.

Inclined Screens: What Everyone Gets Wrong

The long-held belief that inclined screen output always beat horizontals falls apart the moment you look at what actually makes it through the deck.