Built for Uptime: Inside PECO's New Flagship Facility

With centralized dispatch, larger service bays, and faster parts picking, Power Equipment is delivering faster, more efficient support across their territory.

PUBLISHED: NOVEMBER 2025

Service is the differentiator for so many of today’s equipment dealers.

Power Equipment Company (PECO), a full-line dealer representing Superior in five states and two provinces, is doubling down on that belief. Their new flagship facility in Colorado is built to elevate service for end users across the region.

From centralizing service dispatch to leveraging telematics and streamlining work orders, the facility is equipped to keep customers up and running like never before.

“A lot of manufacturers make quality equipment today, but no matter what you do it's going to break,” says Marc Dowdell, president of PECO. “So, the question then becomes: how do you respond to minimize downtime?”

All Eyes on Uptime

Ultimately, PECO consolidated three Colorado locations into one mega facility in suburban Denver. They've been operating in the facility for a few months now following a renovation that began in May.

The new 52,000-square-foot facility is seated on 20 acres, which includes a separate 8,400-square-foot building to secure parts and provide added storage.

A centralized dispatch center is among the new components of the facility. PECO is now coordinating all field service from one dispatch center, delivering faster, more efficient repairs for end users across their territory.

“When you call into a local branch, you’re limited to whoever is available there,” Dowdell says. “But with a centralized dispatch and 45 techs in our bullpen, we can get the right technician, with the right expertise, to the job much faster.”

Additionally, PECO can see its entire service operation in real time — truck locations, active work orders and even weather that could affect travel or repairs. That visibility gives the company a true central command. Technical communicators and the training group are also centralized to keep jobs moving quickly.

“One of the biggest advantages is the visibility,” Dowdell says. “That helps us make smarter decisions and get a customer taken care of much faster.”

PECO is also working toward a proactive approach to service rather than the traditional model of reacting.

“The way our technology works now, customers shouldn’t be calling us to say a machine is due,” Dowdell says. “We should be the ones calling them to say we’re in the area and can take care of the service.”

"Instead of going to a site, we can bring customers into a true classroom and staging area." It brings them closer to us and strengthens that partnership dealers always talk about.”

Parts That Move Faster

Getting parts orders out in a timely manner is also a service priority at PECO, which invested in a vertical storage system leveraging Kardex technology.

“Since we added the automatic storage system, our pick time has been cut in half – from 54 seconds down to 27,” says Dowdell, adding that PECO stores 300,000-plus individual parts across more than 4,000 product lines. "It knows where everything is and alerts us when to reorder, and while we expected to save space, the accuracy and efficiency gains have been the real surprise."

The new shop includes 13 double service bays measuring 25x80, plus a heated indoor wash bay. Three 10-ton overhead cranes and a five-ton crane support heavy component rebuilds and other major repairs.

A training room for up to 50 people is another key feature of the facility. The classroom-style setup gives PECO a place to host traditional training, but the company also made accommodations to make training even more dynamic.

“We can bring education right into the shop,” Dowdell says. “We’ve got televisions on tracks and can roll them right up to a live piece of equipment."

Dowdell points out that the next evolution across the industry is a stronger emphasis on structured customer training.

"Instead of going to a site, we can bring customers into a true classroom and staging area," he says. "It brings them closer to us and strengthens that partnership dealers always talk about.”

Flagship: Phase Two

The site is currently undergoing a second phase of construction that will result in a clean room to perform component rebuilds and a paint booth early next year.

“We’re not quite a finished product yet,” Dowdell says. “We’re about 75 to 80 percent of the way there, and we keep adding capabilities as we go.”

Service is the differentiator in today’s market and Power Equipment Company is proving what it looks like when that belief turns into action.

Other Content This Month

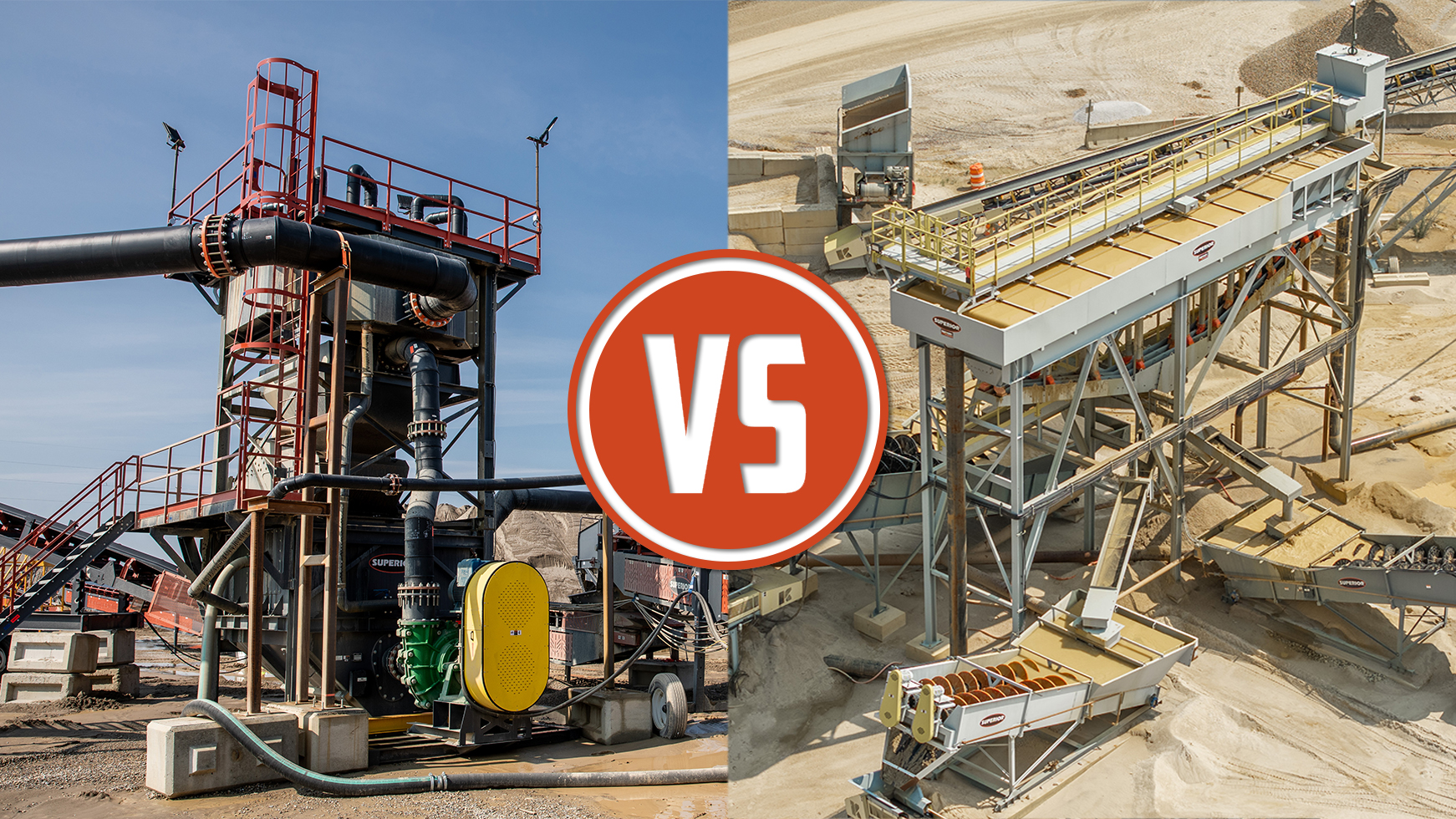

Cyclones vs Tanks: Details Competitors Leave Out

There’s a bold claim out there that cyclones can replace a classifying tank in every scenario. The trouble is, once the feed changes, cyclones are inconsistent.

9 Things We Already Know About CONEXPO-CON/AGG

Scheduled March 3–7, the show is already coming into focus. Here, we’ve gathered some early insights to give dealers a head start on what’s ahead.

Inclined Screens: What Everyone Gets Wrong

The long-held belief that inclined screen output always beat horizontals falls apart the moment you look at what actually makes it through the deck.