Five Expert Strategies to Identify Screen Issues & Boost Replacement Sales

Discover actionable strategies to enhance your sales and service approach, enabling you to diagnose issues and drive potential sales of replacement screens.

PUBLISHED: APRIL 2025

Maybe it's true where you live too, but in the Northeast United States especially, the population of screens tends to skew older.

“It's the oldest part of the country,” says Phil Garinger, a Superior territory manager. “So, the Northeast naturally lends itself to having some of the oldest quarrying equipment."

According to Garinger, EESSCO — Superior's dealer across New England — has recently seen an uptick in the replacement of inclined screens. They're finding lots of producers running screens that are 20 to 25 years old, so a replacement is critically nearing.

Of course, screen replacements aren’t limited to EESSCO or Kemper Equipment and the Northeast region. Superior dealers everywhere can uncover these opportunities just the same.

With help from vibratory product manager Ed Sauser, here are five measures dealers can adopt when addressing screen replacements:

1. Ask Detailed Questions

“If you can get insight on what’s causing them pain, that's when we have our best successes," says Sauser. “When we know the pain points, we can start offering real solutions.”

For example, how often is an operation changing its screen media?

“If they’re changing metal wire every three weeks, that’s a huge expense not only in material, but the labor and downtime is tremendous,” Sauser says. “Go in there with a urethane solution, which might involve upgrading the screen with different decks.”

Superior has a questionnaire that dealers can utilize to more efficiently review questions and capture answers.

“The questionnaire is very helpful in sizing a replacement screen to try to get as much information on first contact,” Garinger says. “If you’re going back three or four times with more questions, the end user loses confidence in you."

Garinger also advises to get drawings of the existing screen. This can be of tremendous value as a replacement is explored.

“Sometimes, I get old pencil drawings and capture a photo of it,” Garinger says. “If the key dimensions are on it, we can reproduce it.”

2. Engage the Front Line

When pursuing a sale, some sales representatives may immediately beeline for the decision-maker, but valuable information can be gleaned from people site wide.

“Don't overlook the valuable resources on the front line,” Sauser says. “Bringing decision-makers feedback from their own operation can go a long way, especially when they might be unaware of certain pain points."

Maintenance personnel can provide valuable intelligence, as well.

“Find their trigger points,” Sauser says. "We offer plenty of ways to address their issues, and when you start providing solutions to problems, the sale gets easier."

3. Walk Around & Observe

Sometimes, pausing and using your senses gets you answers.

“Do you smell any burning rubber or anything hot,” Sauser asks. "Take stroke readings to check if the screen is moving evenly from side to side or showing signs of imbalance."

Sauser also advises dealers to look at the wear patterns on a screen’s sides.

“It doesn’t even have to be running,” he says. “If one sidewall shows more wear than the other, it tells you the material isn't flowing evenly. Maybe the feed isn’t centered or there’s an issue with the feedbox?"

Another basic step is to measure a screen’s springs with a tape measurer to determine if they’re the same length from side to side.

“In screening, everything’s got to be symmetrical,” Sauser says.

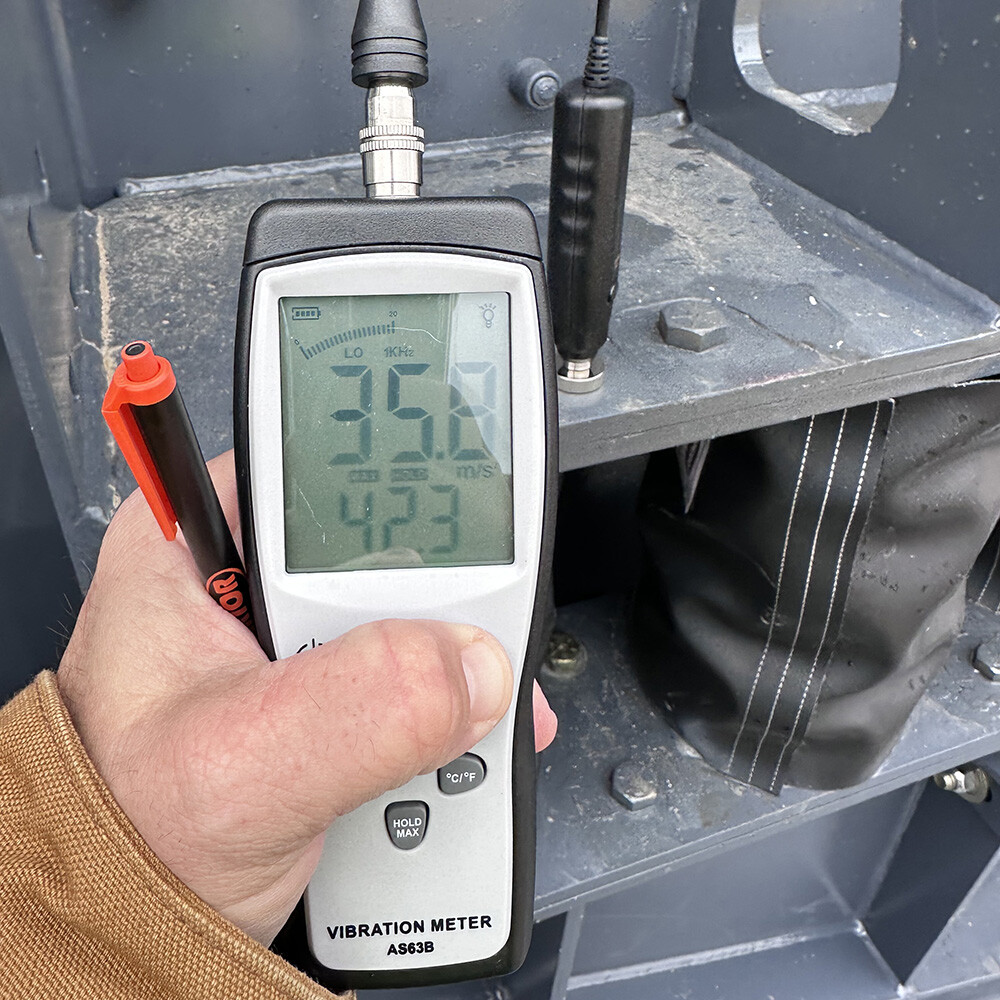

4. Use Technology to Diagnose

Electronics have become more fundamental to analyzing screen performance, so take advantage of it!

“Technology can give you a digital readout of the unit's speed and stroke, so you can make a comparison,” Sauser says. “Some sophisticated technologies use sensors applied to each corner of the machine to detect irregularities that can decrease efficiency.”

Remote monitoring devices can offer an even higher level of intelligence on screen performance.

“Some systems can identify when things change and provide an alert, whether it’s through a flashing light, or even a text or email," Sauser says.

There are many advanced monitoring systems available on the market today, and Superior has begun preliminary development in this area as we continue moving in that direction.

5. Sharpen Your Skills

Superior’s new OptimizeU dealer learning platform gives industry veterans the ability to brush up on their knowledge and educates newcomers before they visit an end user’s site.

“OptimizeU is loaded with all sorts of training videos and interactive content to teach dealers different aspects of screening, whether it’s maintenance, setup or operations,” Sauser says. “There’s a ton of educational material available on there!"

Selling a replacement screen isn’t done overnight. Often, a sale comes down to a factor like trust and whether the salesperson has earned that from the end user.

“The end user might not be ready to replace their screen, so if a dealer can extend its life by several years, that effort won’t be forgotten," Sauser says. "But, you must build that trust.”

Other Content This Month

Double Down: Washing Strategy for Tough Deposits

As the era of clean deposits fades, the need for double or even triple washing emerges, prompting effective strategies to tackle tough aggregate deposits.

110 Features to Know: Patents Deliver Success

With an extensive portfolio of patents, Superior dealers can leverage these unique features in their sales strategies to differentiate themselves from the competition.

Blueprint for Success: Gila River Open House Tour

Learn how Superior and Kimball came together at a newly commissioned wash plant to showcase products and set a new standard for engaging prospects.