Why Dealers Should Get to Know Attrition Mills

With clean reserves dwindling, attrition mills are becoming an increasingly popular solution for producers tackling dirtier deposits and tougher specs.

PUBLISHED: SEPTEMBER 2025

In the decade since we began manufacturing processing equipment, we’ve introduced dozens of new products and hundreds of models. Given the breadth of our lineup, we've often noticed producers respond with, ‘We didn’t know you made that!’

This is one of those products...

Why Should I Care?

Attrition Mills are high-energy machines that scrub stubborn clay and silt from sand and are often overlooked in Superior’s lineup. Yet dirtier deposits are making them more relevant than ever.

Many premier reserves are already mined, leaving producers to double or triple wash material to reach a saleable spec. Screws, cyclones, and classifying tanks can only go so far. In some situations, an Attrition Mill is the best way to free sand from clay coatings.

“They're going to be needed more and more as pits get dirtier,” says Brett Casanova, washing product manager at Superior Industries. “Today’s clay-coated sands often require more agitation and retention time to be saleable.”

When Is It the Right Tool?

Historically, Attrition Mills served frac-sand producers, breaking down small clumps of sand grains bound by clay, silt, or other contaminants. They remain relatively uncommon because they are high-cost, high-wear machines.

“Much like running a VSI crusher, an Attrition Mill can be expensive to operate,” Casanova notes. “Unless you’re selling a higher-value product, it’s hard to justify.”

Dealers should avoid presenting the product as a cure-all. Instead, start with a thorough analysis of the end user’s product specs, current equipment, and wash processes.

Case in Point: RiverBend Materials

Superior and dealer partner Kimball Equipment followed this approach with RiverBend Materials, a CRH company in Oregon.

Like most producers, RiverBend tried washing its sand in multiple stages. It never passed for spec.

After lab testing, Superior recommended two attrition mills (four tub cells total)—an uncommon setup but one that delivered the cleanest C33 sand RiverBend had ever produced.

“It all started with getting a good sample into our Nebraska lab,” Casanova says. “Once we understand the material, we can pinpoint how much agitation and retention time it takes to bring the sand into spec.”

What Should I Do?

Dealers play a central role in making attrition solutions work, beginning with a full range of sampling and regular communication.

Because material varies across any alluvial deposit (sand and gravel left by rivers) testing requires a true picture of the site. Collect material from:

- Dirtiest Area: Where the material carries the most clay or silt.

- Cleanest Area: The best-quality sand and gravel from the site.

- Typical Mix: Material that falls between those two extremes.

“This range of samples is essential for accurate testing and equipment recommendations,” Casanova says.

Once the system is defined, we can review feed strategies with your customer.

“If the pit runs especially dirty, they may need to slow the feed or blend in cleaner material to keep the system working,” Casanova advises.

Dirty deposits aren’t going away. When a producer struggles to meet spec after conventional washing, let's chat. Gather samples, send them in, and we’ll help determine whether an Attrition Mill is the right answer.

How does an Attrition Mill work?

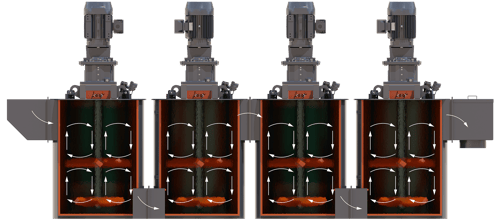

An Attrition Mill cleans sand by forcing the grains to scrub against each other, stripping away clay and silt coatings.

-

Material Feed

-

Sand and water slurry enter the first cell through an inlet. The mixture is kept at a controlled solids percentage to promote particle-on-particle action.

-

Intense Agitation

-

Opposing high-speed propellers create an aggressive scrubbing action. Grains collide removing clay, silt, and other coatings.

-

Extended Retention

-

Units are typically arranged in pairs. Each new cell provides additional retention time and repeated scrubbing for stubborn coatings.

-

Clean Discharge

-

Freed clays remain suspended in the water while the cleaned sand exits for final washing or classification.

Other Content This Month

Dealer Exclusive: Product Lineup for CONEXPO-CON/AGG

The industry’s biggest event is just months away. In this Orange Edge exclusive, get the first look at equipment we’ll showcase at CONEXPO-CON/AGG 2026.

Remote Crusher Monitoring Ends Blind Service Calls

Vantage® Automation will soon integrate remote monitoring into key crusher lines, with a package planned for demonstration at CONEXPO-CON/AGG 2026.

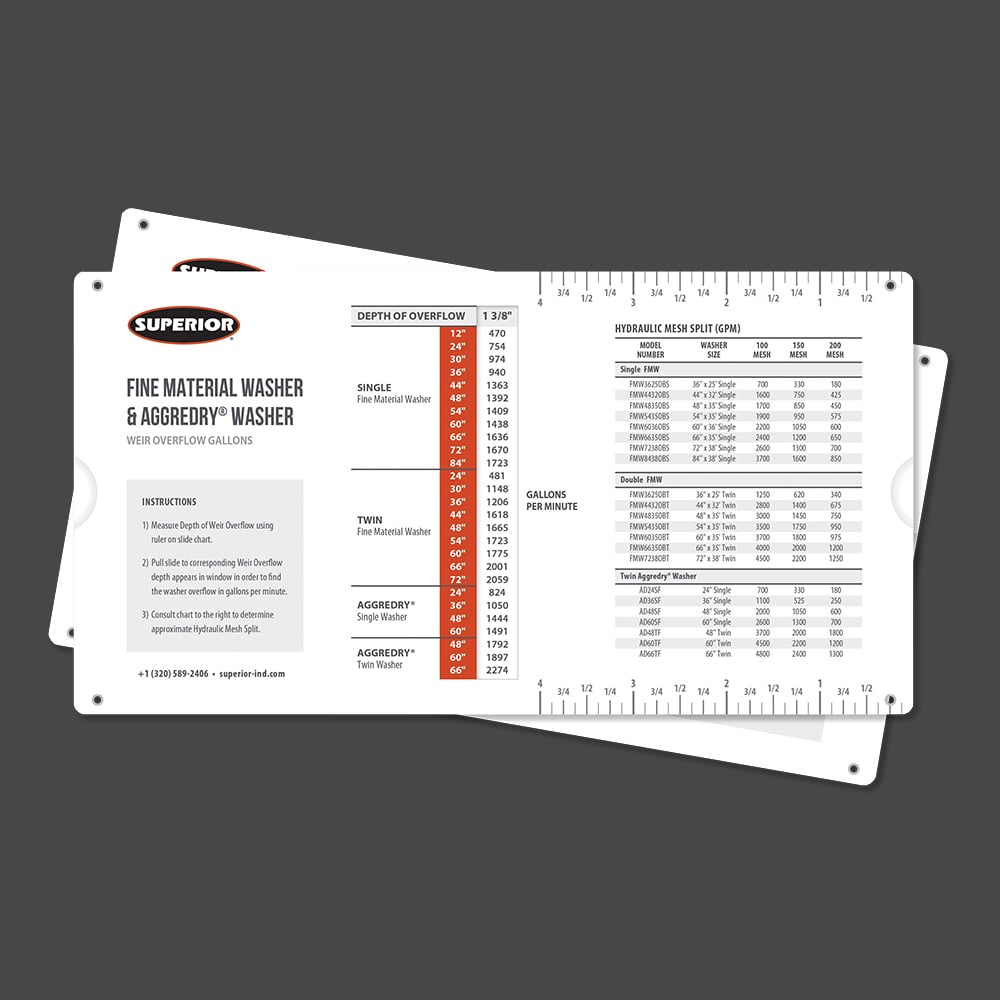

Claim Your Free Sand Washing Pocket Guide

Quickly access calculations for weir overflow rates, screw speed, hydraulic mesh splits, and other fine material washer performance data.