HSI Cheat Sheet: Match the Model to the Mission

Choosing the right horizontal shaft impactor isn’t one-size-fits-all. This breakdown helps dealers align machine performance with applications.

PUBLISHED: JUNE 2025

Understanding the material and end goals of an operation is critical to any crusher installation, and horizontal shaft impactors (HSIs) are no different.

“When we understand the application and what the producer is trying to achieve, we can fine-tune elements like rotor speed, blow bar setup, and curtain settings,” says Jarrod Adcock, crushing product manager at Superior. "That makes it much easier to get the crusher dialed in for success from startup."

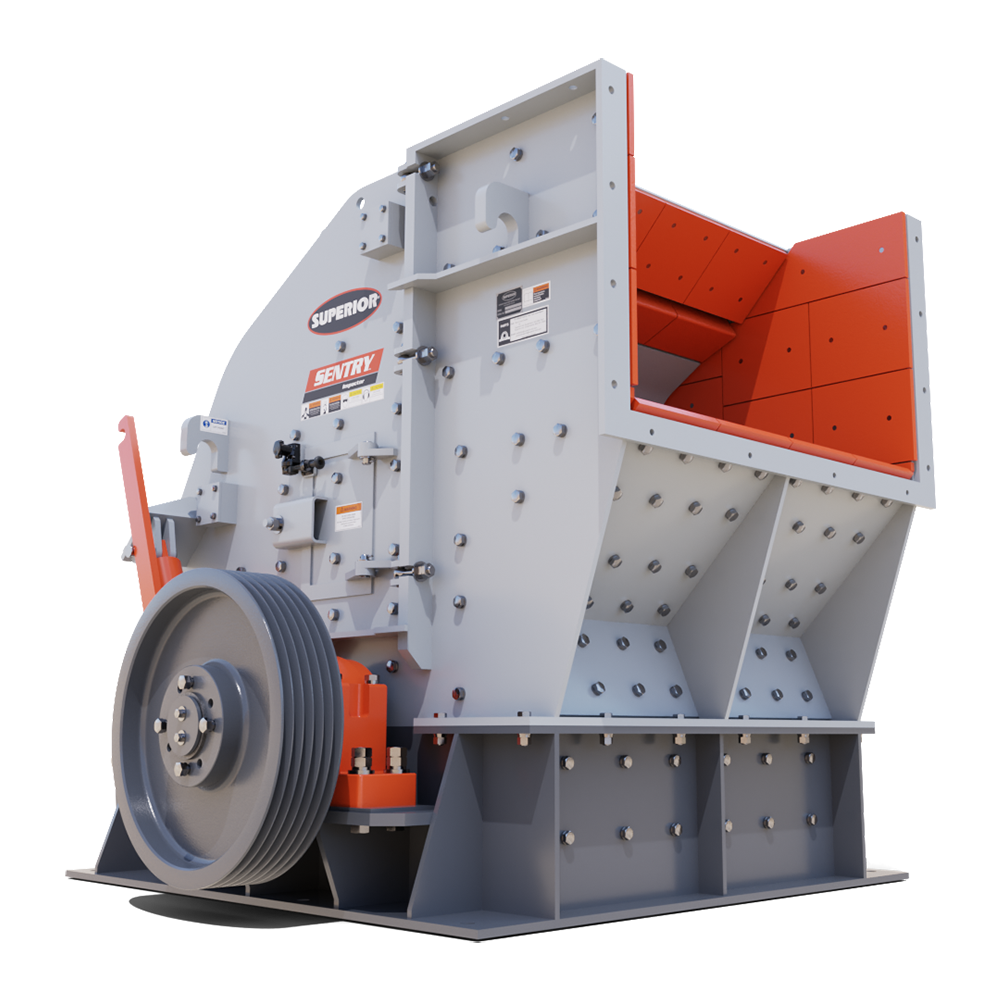

That’s why Superior offers three distinct Sentry® HSI models, each engineered a bit differently to meet the demands of specific jobs.

SP: Primary Models

Designed for primary crushing, SP models range from 350 to 700 horsepower. The smallest handles feed up to 24 inches, while the largest processes up to 40 inches.

SP models include a cast monoblock primary curtain with replaceable wear tips and a fabricated secondary curtain with replaceable liners. Adjusting curtain settings helps dial in the desired product size.

“These models also feature fabricated, open-style rotors, which can be configured with two, three or four blow bars,” says Adcock. “Bar count can affect things like fragmentation, wear life, and throughput."

For example, a four-bar rotor typically produces finer material and higher capacity, while fewer bars may lead to coarser product.

Originally, SP models were available with either two- or four-bar rotor setups, but a three-bar option was recently added for more flexibility.

“We’re trying to cater to many different applications,” says Adcock. “Some customers prefer a three-bar rotor simply because it’s what they’re used to running.”

Why More Operators Are Choosing Sentry HSIs

Superior’s product management team shares how Sentry® Horizontal Shaft Impactors are gaining traction with end users, thanks to unmatched simplicity and flexibility.

SS: Secondary Models

The SS range includes four Sentry HSI models, spanning 150 to 800 horsepower. They feature a slightly smaller feed opening and incorporate a multi-curtain design to control reduction.

“These have fabricated primary and secondary curtains with replaceable liners,” says Adcock. “They also feature a fabricated open-style rotor, available in two-, three-, and four-bar configurations.”

All four SS models can also be equipped with an optional grinding path, a feature that's often confused with a third curtain.

Unlike a third curtain, which is usually fixed, a grinding path is an adjustable component. It’s designed as a retractable cartridge that can be moved closer to the rotor. This creates an additional stage of reduction, improving the final product shape or size consistency when needed.

SR: Recycle Models

Superior also offers Sentry HSI models specifically designed for recycling and demolition applications. The SR line is built to handle tough, irregular material like slabby concrete and rebar.

There are three SR models available, all featuring larger feed openings to better accommodate harsh, oversized material.

Additionally, SR models are built with a cast primary curtain with replaceable ends, a fabricated secondary curtain with replaceable ends or liners, and a cast-enclosed rotor.

“Whether it’s rebar, steel rods, or any kind of matting, the tramp won't get tangled up like it might in a traditional open-style rotor,” says Adcock.

Among the lineup — which also can be configured with two, three, or four blow bars — the SR4250 has proven to be the most popular.

“That was the one that kicked us off,” says Adcock. “It’s the same model we brought to CONEXPO-CON/AGG mounted on a portable plant in 2023.”

The larger SR5165 is gaining strong traction in the field, while the compact SR3936 is showing promising potential for future growth as demand increases for smaller, more versatile machines.

Application Fit Builds Momentum

Despite distinctions between models, Adcock says some end users still try to stretch HSIs beyond their intended use. It’s a move that often leads to underperformance and frustration.

“There were attempts to put a recycle model in a secondary application," he says. "In certain circumstances you can, but the machine’s not optimized for it.”

Some of the bigger dealer victories involving Sentry HSIs were scored because of application fit. And those wins have led to follow-up victories.

“Our reputation as a serious market contender for these machines is definitely growing," Adcock says. "It’s getting easier to share success stories and build confidence.”

Credibility grows fastest when the model matches the mission.

Other Content This Month

Washing School Recap: Five Hot Topics to Know

From man sand to water recovery and equipment overlap, here are topics that got the most attention at our recent Washing Equipment Dealer Sales School.

Dust Compliance is Coming: Are Your Customers Ready?

With regulations tightening, dealers have a growing chance to offer dust control solutions that improve performance and open the door to upsells.

The Updated Field Guide Delivers Real-World Support

From updated specs to troubleshooting tips, this hands-on reference helps your team spec, service, and sell Superior equipment with confidence.