Tech Tip: Modern Wing Pulleys

Extend Belt Life With V-Shaped Model

When “auditing” material handling systems, productivity and profitability is seriously affected by such issues as periodic pulley failure, conveyor belt repair or replacement, and frequent maintenance downtime. Yet it is not uncommon for operations to stick with certain traditional or conventional conveyor components even though they are one of the underlying causes of ongoing, costly maintenance challenges.

In bulk material processing operations, material handling costs are spread over the useful life of conveyor systems and components. Higher initial costs may be recouped in lower maintenance and operational costs over time if the right decisions are made when the equipment is specified and ordered.

V-Shaped Wings

Today, solutions to greater efficiency are imperative. The latter is the market driver behind conveyor component innovations that truly tackle the maintenance challenges that occur every day within bulk material handling applications.

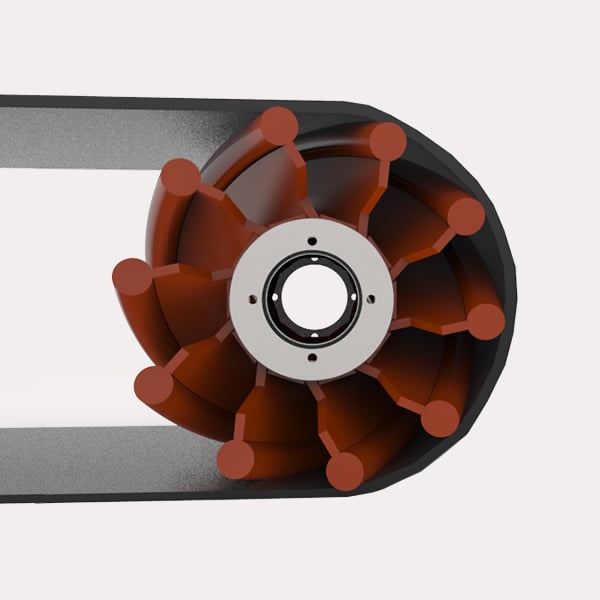

One of the most innovative conveyor component solutions in recent decades is that of the V-shaped wing pulley, patented by Superior Industries as the Chevron® Pulley.

While extending pulley life, its V-shaped design is engineered to prevent material buildup and belt damage while greatly minimizing noise and vibration during operation. When compared to the conventional wing pulley, the V-shaped pulley design delivers numerous time-and -money saving advantages over that of traditional choices.

Traditional Challenge

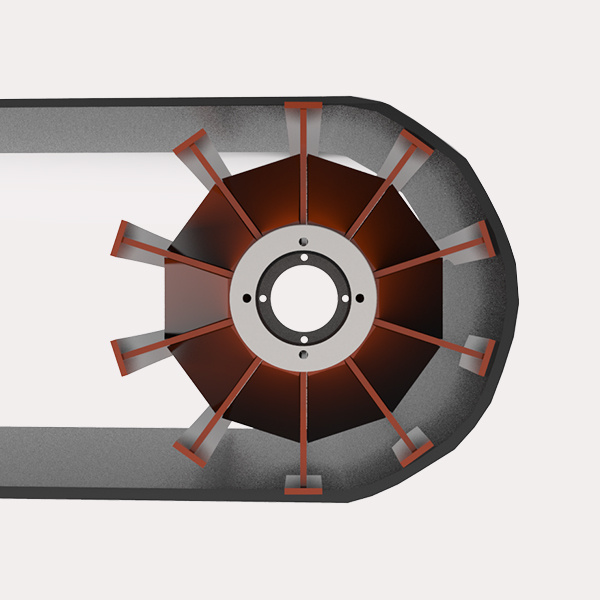

The conventional wing pulley is particularly susceptible to buildup, wing bending, as well as noise and vibration during operation.

First, degraded material, which breaks into smaller parts, can be carried between the belt and the pulley, causing excess wear and tear on the belt, as well as potential belt slippage and mistracking. Large entrapped material with sharp edges can create an uneven belt surface and can puncture, gouge or rip the belt. Also, trapped material can be ejected back onto the return side of the belt and can become entrapped in the pulley repeatedly until it finally degrades; or until it damages the pulley face, bends the pulley wings, or causes pulley or belt failure.

Removing material buildup from the pulley or repairing or replacing pulleys and belts results in significant downtime and maintenance costs.

Wing Alternative

Due to its V-shaped wing configuration, the Chevron Pulley deflects material away from the pulley and belt, minimizing the potential of pulley or belt damage. The V-shaped wing configuration also results in continuous belt contact. Its round-edged wings overlap along the length of the wing pulley to permit the conveyor belt to be supported by multiple wings along the belt width. This eases the transition of belt contact from one wing to the next, which in turn, minimizes vibration to the belt, extends belt life, and reduces the amount of noise generated by the wings contacting the belt.

In comparison to the conventional wing pulley, the V-shaped wing pulley deflects material far more effectively, while providing smooth operation with less vibration, less belt wear, less of an impact and load on the bearings, and less noise. Operations realize greater safety via reduced levels of hazardous vibration and harmful noise.

Downtime and maintenance costs are minimized and significant cost savings are realized via extended pulley and belt life.

Conventional Comparison

What is the engineering and design intent behind the V-shaped wing pulley that allows it to self-clean or shed material, as well as prevent the tendency for bent wings? And, how does it primarily differ from conventional wing pulleys?

On the V-shaped wing pulley, the rock does not hit at a direct impact but rather at a glancing blow. The V-shaped wings deflect fugitive material out and away. This prevents rocks being wedged between the wings and the belt, and lessens the possibility of wing tipping and belt damage. As to the conventional wing pulley, the impact of the rocks is directly perpendicular to the wing. Material is more easily entrapped between the wings, which over time can cause the wings to bend. Importantly, the conventional wing generally ejects the material forward, so that the material has multiple opportunities to make its way back into the wing pulley.

For the conventional wing to work the way it was initially designed, it has to rotate very slowly so that the material can fall into the wing, hit the gusset and fall out of the wing. Otherwise, the wings will simply propel the material forward again and again, until it finally falls out or becomes entrapped.

The V-shaped wing pulley has a round-end view, which allows continuous belt contact. The belt is essentially rolling around a circle, which significantly reduces any beating action on the belt and greatly extends belt life. On the other hand, the conventional wing pulley is “apexed” or is shaped as a many-sided polygon. So the belt is always raising and lowering over one or two wings as the pulley is going around, which causes the belt to flap and results in more belt wear, and much more vibration and noise.

Tests have shown that the conventional wing pulley operates at an average 120-noise decibel level, while a Chevron V-shaped wing pulley averages only 70 decibels.

Also, conventional flat bar wing pulleys have sharp edges on the corners, while the V-shaped pulley wings are rounded on the edges to avoid the potential of puncturing a belt or catching on a splice. Importantly, when a conveyor belt stretches around a conventional wing pulley, it stretches over each wing bar, which leads to accelerated wear and tear on fasteners and splices, as well as the potential for belt mistracking.

OptimizeU - Strategic Learning

Pursue greater production with comprehensive online courses in crushing, screening, conveying, and washing. Check out the premiere training resource in the construction aggregates industry.

Related Content

Conveyor Pulley Shafting: Proper Selection Matters

A conveyor pulley assembly is an integral structure that relies upon the pulley and shaft working and functioning together.

Conveyor Pulley Lagging: The Rubber Layer That Decreases Downtime

When seeking highly efficient and economical conveyor operation, proper pulley lagging is an integral detail.

Crown Face Pulleys: Is There Value?

Many think that a crowned face pulley is a must, but its value to belt training might be more myth than reality.

Talk to an Expert

Need more information? We'll get you in contact with a product expert in your area.