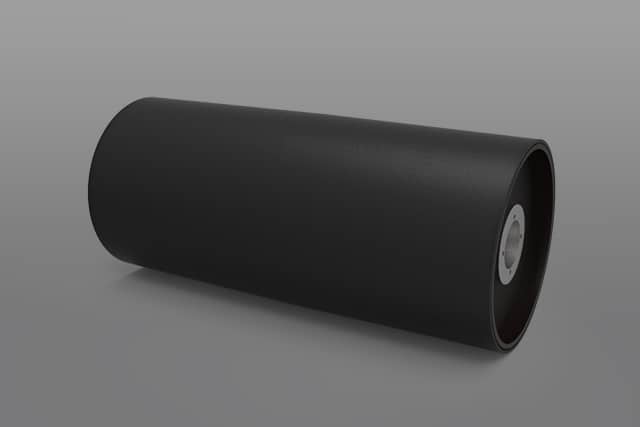

Conveyor Pulleys

Lagging Decreases Downtime

Lagging increases the traction between the belt and the pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings, and

take-up. Proper selection is integral to highly efficient and economical conveyor operation.

Lessons Delivered:

- Benefits of pulley lagging

- Recommendations for application

- Lagging specification tips

Related Content

Conveyor Pulley Manufacturing: Superior’s Tried & True Approach

Pulleys are the heart of any conveying system and maximum life is essential to cost-efficient, high-capacity production.

Dry Bulk Conveyors: Basic Design For Better Maintenance

Designing a conveyor to be maintenance friendly means providing adequate provisions for necessary service from the onset.

Conveyor Wing Pulleys: Extend Belt Life with V-Shaped Model

It is common for operations to stick with traditional conveyor components even though they are causing maintenance challenges.

Related Products

Talk to an expert

Need more information? We'll get you in contact with a product expert in your area.